L3 - Fiber laser

The software ecosystem

STREAM defines the production process according to the best processing sequence, taking all variables, including production costs, into account, and starting with the model of the finished product. It is structured on three levels: technical,productionandbusiness.

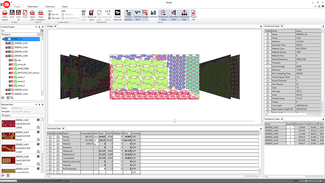

Technical

STREAMLASER is the programming software for the generation of cutting programs. It consists of the following modules:

- CAM for the part: creates or allows for changes to be made to a 2D model and automatically defines lead-ins and cutting sequences.

- CAM for the sheet: calculates the processing path and the movements between one processing and another, and decides the cutting tool, permitting manual interventions thanks to a powerful interactive editor.

- NESTING for automatically, semi-automatically or manually composing the sheets from the list of parts to be produced; it re-orders the lists generated so as to optimize production on systems equipped with an automatic store-tower.

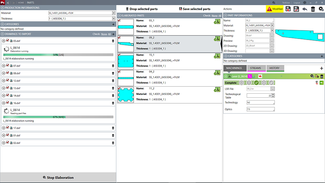

Production

The PARTS software manages the database of the entities that define the production flow for a part or group of parts by:

- classifying the parts according to common categories (size, material, thickness, etc.) or categories personalized by the customer (project, kit, etc.).

- defining one or more production flows for each of the parts to be made on Salvagnini systems.

- generating the programs for the technologies present in the production flow for the part to be made.

Business

VALUES is the software for estimating the production costs for a part in the production flow by:

- providing the final cost of entire production batches, nests and single parts in a simple and efficient manner.

- managing the costs relating to electrical energy, manpower, materials and depreciation and automatically converting prices into the main currencies.

- taking into consideration the work carried out on Salvagnini or third-party systems (painting, welding, etc.).