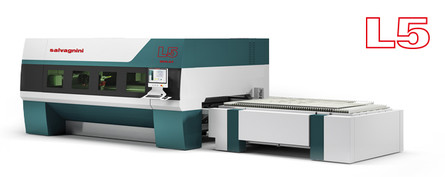

S4 - Punching-shearing center

Salvagnini automation in the S4 punching-shearing center: no intermediate handling, unattended production, and even lights-out manufacturing.

Feeding solutions

The S4 punching-shearing center can mount different types of feeding connections: from in-line conveyors and automatic destackers to automatic single-towersheet stores and multi-tower tray storage systems.

The MD store is an automatic store for packs of sheet metal that feeds the machine with single blanks in masked time. This solution covers a wide range of storage needs, eliminating unnecessary material transfer and facilitating the just-intime or kit production of parts using different gages and materials.

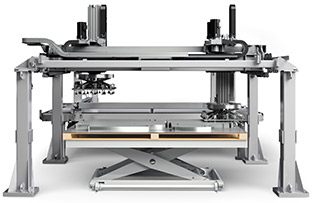

Unloading solutions

The punched and/or sheared parts can be automatically directed to different collection bins, to buffer stores, to one or more stackers, to intermediate stores or straight to other machining centers.

The Salvagnini MC Cartesian unloading robot picks the punched and/or sheared parts up as they leave the S4 punching-shearing center and stacks them on one or more tables thanks to two manipulators with suction-cup gripping that run along a carriage and can rotate around a vertical axis. Manipulator rotation allows the parts to be stacked and positioned correctly for the subsequent processes.

The two manipulators can work either independently or simultaneously if required by part dimensions.