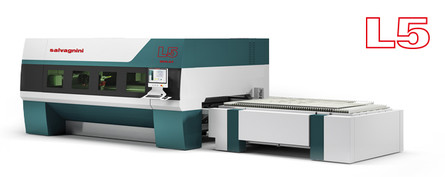

ROBOformER - Robotic bending cell

An exclusive programming suite: designed and produced by Salvagnini for the ROBOformER

METALStudio

METALStudio represents the CAD platform that the Salvagnini CAM applications (punching, laser, bending and forming) draw from. Using a solid modeler and user interface, both designed specifically for the purpose, METALStudio automatically unfolds 3D drawings and calculates the bending tolerances for the material used, ensuring that the part is cut to the precise dimensions.

TOOLformER

When METALStudio imports a new drawing, the Salvagnini TOOLformER module, which has the job of integrating the management of tools, robot gripping device, back-gauge fingers and so on; it also provides a guide for the press-brake setup best suited to the part. Tools can also be determined by importing the corresponding drawings.

CAMformER

CAMformER generates the complete program for the production process, regardless of whether or not the robot is to be used. Programming takes place in a single environment, meaning that the user does not need to know how to use a number of different software tools in order to run the press and the robot. The optimal bending sequences, gripping maneuvers and robot trajectories are calculated automatically.

The complete job program is then sent to the cell's single controller for execution. The user can decide whether to optimize the production phases off-line, without stopping the machine so as to teach the robot, or to perform this optimization directly on the machine computer. The simulation software gives a realistic stepby- step preview of the bending cycles with 3D animation, providing an accurate estimate of cycle time and elaborating a series of reports to help in setting up the configuration of the system.