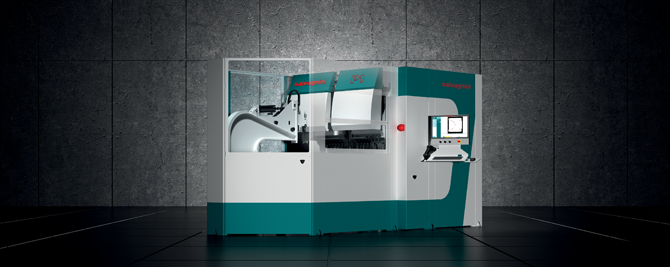

P1 - Versatile and productive electric panel bender

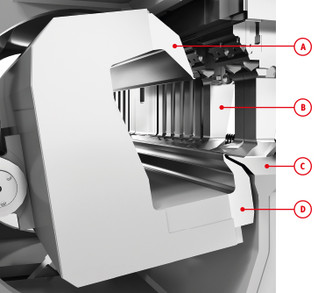

Upper and lower blade, counterblade and blankholder are the four universal tools used to process the whole range of thicknesses and machinable materials, from 0.4 to 1.6 mm, during the cycle and without machine down times or manual re-tooling.

The upper and lower blades (A, D) are the two tools that feature interpolated controlled movement and are responsible for bending; the counterblade (C)helps clamp the sheet during the cycle; the ABA automatic blankholder (B) works simultaneously with the blades and counterblade to bend and clamp the sheet accurately and effectively. It adapts the tool length according to the size of the part being produced during the cycle, without machine down times or manual re-tooling. The tool profile allows inward bends up to 45 mm.

Automatic manipulator: fast and accurate.

Quickly and fully automatically, this moves, handles, grips and rotates the sheet metal throughout the whole machining cycle. It requires no manual interventions during the cycle. The operator positions the sheet metal on the worktable and collects the product after bending, performing only the loading and unloading operations.