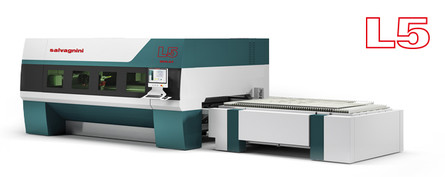

L5 - high dynamics fiber laser

The compass: high dynamics and low consumption

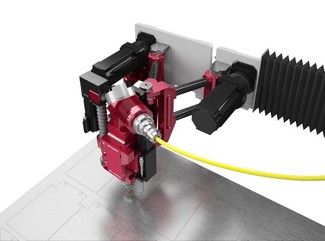

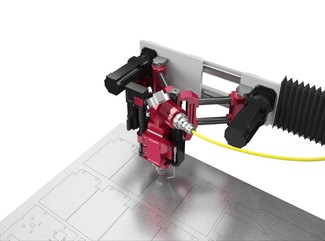

The compass is the very heart of the mechanical solution. This structure is made possible by the absence of a defined optical path and features carbon arms driven by a pair of rotary motors that move the cutting head on the XY plane in small steps. Dynamics are up to 5g, as offered by linear motors, but on account of the light weight, energy consumption and running costs are cut and kept competitive.

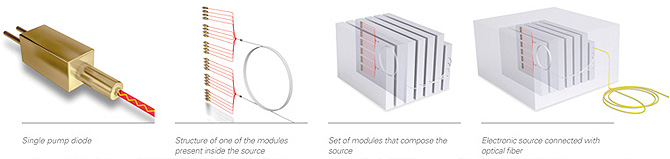

Electronic source and fiber-carried beam

In Salvagnini laser systems, the laser beam is generated and carried by the fibre. The beam is generated by an electronic source, which comes in various output powers (2, 3 and 4 kW), while it is carried by a standard fiber, with no optical path required.

The laser beam generated and transported in fiber up to the cutting head guarantees:

- Lower consumption, thanks to the highly efficient source (40%).

- Drastically reduced costs for maintenance and consumables, thanks to the absence of an optical path.

Our experience at your service...on the machine

TRADJUST is the set of functions in the Salvagnini SiX controller that automatically modulate the cutting parameters in accordance with trajectories, speed and acceleration. This makes the L3 a simple system to use, because it has only one cutting parameter for each material and thickness, regardless of the dimensions of the cutting profile.

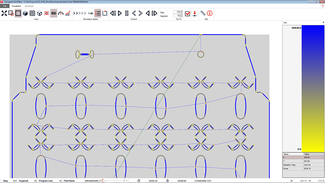

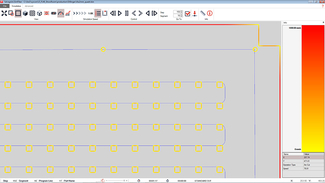

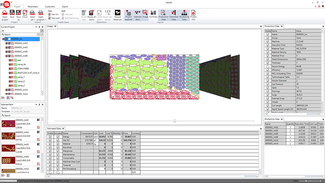

Our experience at your service...in the office

The THTables integrated into the STREAMLASER programming software, offer large geometric and technological parameterization, dedicated to fiber, and allow for a robust, optimized program to be generated in the office.