S1 - Mechatronic punching machine

Automation within the reach of everyone

Salvagnini offers extremely flexible systems that are suited to all production needs and able to reduce production and management costs while satisfying the most modern manufacturing strategies and the most competitive production trends. The feeding and unloading connections make it possible to optimize the production flow, eliminating non-productive operations and their related costs, while keeping the level of product quality and profitability high. For feeding S1 can provide, in an increasing order of automation, different types of connection: manual, from a pack via a suction cup device or with a single sheet (MD) or pack tower. Similarly, unloading can be manual, or automatic with the unloader on a dual-position table or with a Cartesian manipulator MCU. Thanks to different handling devices, S1 can operate without the presence of an operator and is suited to working in line, by means of conveyors connected to a panel bender, or in stand-alone mode, in which case it becomes a productive and flexible tool suited to those who are looking for intelligent affordable solutions and competitive operating costs.

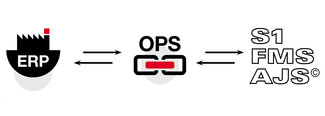

Integrated communication and flexible automation

Thanks to proprietary software, S1 can exchange information with the company ERP or communicate with other systems: for example, in the FMS S1+P4 lines, dedicated software allows the two systems to communicate with each other, balance production in order to increase productivity as well as reduce waste and wait times. In the flexible cells which include an S1 and bending solutions as B3, P1, P2 or P4, the OPS software makes it possible to optimize the work and guide the operator during part production.

FMS and unmanned in-line manufacturing

The S1 punching machine lends itself to working in line with the P4 panel bender thanks to the handling and transfer devices that connect it mechanically and the communication software that allows bi-directional communication between the two systems, even with unmanned operation. The combination has been designed to run kit or batch-one production - or process other series of parts that differ from each other - in an efficient flow, without work-in-process, avoiding intermediate sheet handling and, thanks to automatic blankholder set-ups and the multi-press head, without set-up times. It is the ideal solution for companies seeking responsiveness, i.e. wanting to run operations without restrictions, on a just-in-time basis, reducing stock to zero, or kit, batch-one while still having the utmost flexibility.